Paper mill wastewater treatment

If you need a paper mill wastewater treatment unit, please contact us for a free survey and consultation.

To learn more about paper mill wastewater treatment, read the following article carefully.

097 222 1608If you need a paper mill wastewater treatment unit, please contact us for a free survey and consultation.

To learn more about paper mill wastewater treatment, read the following article carefully.

097 222 1608

Alkalizing powder cooking technology

Hasy Environment is a consulting unit, providing wastewater treatment systems with many years of experience in the field of wastewater treatment.

We are confident in meeting the strict requirements given by our customers. Aiming to jointly build and develop sustainable, environmentally friendly sesame production

Expenditures set for a project by Hasy Environment

Based on the input ingredients of raw materials, paper factories use appropriate production technology. No matter what paper production technology is used, it still requires a fairly large amount of water. in the production stages. The amount of wastewater generated ranges from 0.06-50 m3 / ton of product. In fact, we need to treat that amount of polluted water before discharging it into the environment.

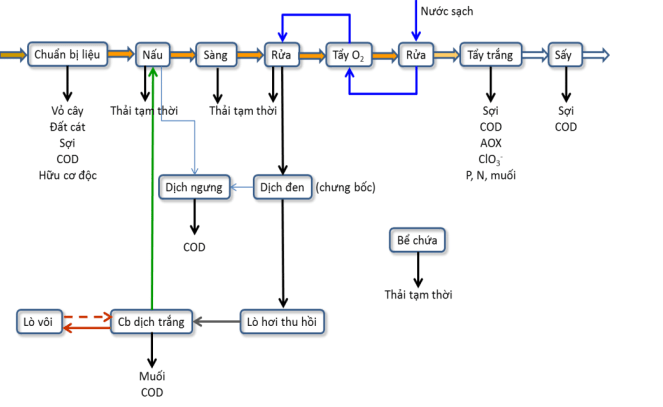

Chemical powder technology is one of the paper production technologies used by many factories. The essence of this technology is to use chemicals to dissolve components other than cellulose fibers in raw materials. into fibrous cellulose.

Alkalizing powder cooking technology

Depending on the raw material source for paper or pulp production, the wastewater generated has specific pollution indicators.

Wastewater composition of some factories producing paper and pulp from wood and waste paper

Technology diagram for wastewater treatment of raw paper mills from scrap paper

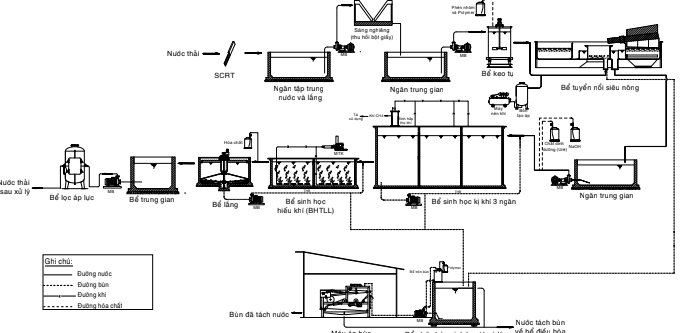

Wastewater generated from production stages along with domestic wastewater (after passing through the septic tank) are collected into the equalization tank.

The conditioning tank is divided into two compartments. A compartment to store wastewater from the textile factory. The remaining compartment contains wastewater from the flour factory. Part of the wastewater from the paper mill is used to dilute the powder solution at the pulp mill. The remaining wastewater from compartment two is pumped to the wastewater treatment station. The wastewater treatment plant includes three main stages: long fiber pulp separation stage, flotation stage, and biological treatment stage.

From the equalization tank, wastewater is pumped to 02 inclined sieves (with hole size of 0.65 mm). Intended to separate residues larger than or equal to 0.65 mm in size (containing long fiber pulp). The powder located on the inclined screen flows down the collection trough to the screw press. To separate water and reuse pulp. The water passing through the sieve is concentrated in the tank and pumped to the flotation tank.

Wastewater mixed with short fiber pulp passes through the inclined screen and wastewater from the screw press concentrates into the compartment, then is pumped to the super shallow flotation system to separate short fiber pulp. Before entering the super shallow flotation tank, wastewater is injected with chemicals (aluminum alum and polymer) and the mixture of water and chemicals is pumped into a pressure device (compressed air) and enters the flotation tank. Scum and sludge in the flotation tank are collected by the scraper system into the central vertical pipe, then sent to the sludge tank. The flotation-treated water flows into the intermediate tank, where a portion of the wastewater is pumped to the powder factory for reuse, and the remainder flows into the biological treatment cluster.

Water after flotation treatment is pumped into a three-compartment anaerobic tank (installed with a stirrer system). This is to remove organic matter (BOD5). Here NaOH solution and nutrients are added to ensure the pH is maintained in the range of 7.5-8.0. At the same time, it adds nutrients for microbial growth. Biogas produced from anaerobic digestion is sucked by an exhaust fan to a gas absorber to remove H2S, NH3, water vapor, etc. The remaining CH4 gas is directed to the boiler area for combustion to provide heat. for boiler. In the anaerobic tank, the sludge settled in the third compartment is circulated to compartments 1 and 2 to replenish the sludge.

Wastewater after the anaerobic tank is pumped through the aerobic activated sludge tank. Under continuous air blowing conditions, aerobic microorganisms exist in a suspended state (activated sludge) mineralizing organic compounds in wastewater into CO2 and water. After the aerobic activated sludge tank, the wastewater flows to the settling tank to separate biological sludge flocs. Part of the settled sludge is circulated to the aerobic biological tank. The remainder is sent to the sludge tank.

The settled water automatically flows to the intermediate water tank. From here, part of the water is reused by a circulating pump to wash the nets of paper machines or pumped into a pressure filter tank (sand and activated carbon) to remove suspended sediments and organic substances that are difficult to biodegrade. remaining after biological treatment before being discharged into receiving waters. The treated wastewater meets QCVN 12:2008/BTNMT

The amount of sludge generated from the flotation and biological stages is brought to the sludge tank. After stabilization, the sludge is pumped to the sludge press for dewatering. Polymer (cationic) is used to increase the dewatering efficiency of sludge. Water from the sludge system is circulated to the sump.

Why choose?