Enterprises and manufacturing plants today are aiming to use advanced air filtration technologies that are both highly effective and cost-effective.

Continuing the series on methods exhaust gas treatment,

One of those technologies is exhaust gas treatment using the Cyclone method. Use cyclone in exhaust gas treatment. The purpose is to separate the huge amount of dust and smoke from the mixture of gases emitted into the environment.

This method is mainly used to use centrifugal force to filter dust and dirt through two ways of filtering dust: dry cyclone and wet cyclone.

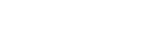

Cycron dust filter equipment in exhaust gas treatment by cyclon method

Besides the cloth bag dust filtration method or inertial dust filtration method, the vertical centrifugal dust filtration method with a cyclone is considered a treatment method. Simple, effective and commonly used.

The method is suitable for dust of different sizes. However, a single cyclone effectively filters dust from 15 micrometers to 20 micrometers.

For dust with smaller sizes below 10 micrometers to 5 micrometers. The cyclone can be improved by second circulating filtration or combined with another dust filter device.

Besides, to increase dust filtration efficiency, multiple cyclone devices can be paired inparallel or in series.

Exhaust gas treatment by cyclone method is used in many industries such as pulp and food production livestock, cement, fertilizer production, sifting, crushing, grinding and screening processes, etc.

Structure of Cyclon device

Vertical dust filter equipment is often called Cyclon. This device has a very diverse structure, but in basic principle consists of the following parts.

Image of Cyclon device structure

The main parts of the Cyclon device include:

- Air inlet

- Vertical cylindrical body

- Dust hopper

- Dust exhaust pipe

- Clean air exhaust

- Valve to discharge dust

Principle of operation of cyclone device

Diagram of the operating principle of the cyclone system

The Cyclon device operates according to the following 4-step mechanism

Step 1: Air flow follows the pipeline into the inlet of the device.

Step 2: After entering the device, follow the door. The airflow containing dust enters the body of the cyclone in a tangential direction to the body of the cyclone in the upper part. Then gradually spiral down along the height of the device to meet the funnel-shaped body. The exhaust fan helps dust move in a spiral direction.

Step 3: Dust, under the effect of centrifugal force, is thrown into the tube wall, gradually losing velocity and falling downwards.

Step 4: The vortex containing clean air gradually reduces the vortex diameter and points upward and out through the middle cylinder and out through the air outlet.

Advantages and disadvantages of the cyclone method in exhaust gas treatment

Which equipment or method is applied to exhaust gas treatment also has its own advantages and disadvantages, and cylon equipment also. The advantages and disadvantages of this method are listed in the table below.

| Advantages | Disadvantages |

|

|

Image of exhaust gas treatment system using Cyclon method

Currently, there are many methods being applied and deployed in treating exhaust gases. Treating exhaust gas by the cyclone method is a simple method, has low investment costs, is easy to operate and is suitable for current industries such as cement production, wood processing, fertilizer production, and manufacturing. paper and pulp…

Join hands to protect the ecosystem and human health by thoroughly applying technical measures in exhaust gas treatment. . Hasy Environment is one of the units specializing in treating exhaust gases with many different methods. Please call for the most detailed advice