The cleaning methods of exhaust gas are very diverse, differing in equipment structure as well as cleaning technology.

To achieve high efficiency in exhaust gas treatment, it is necessary to use a combination of many different filtration methods and equipment at the same time.

One of the ways exhaust gas treatment is quite effective and thoroughly contributes to protecting the environment. is chemical treatment of exhaust gases.

In this article we will help you understand:

If you really want to understand, read the content below carefully

General introduction exhaust gas treatment by chemical methods

Principles of chemical methods in exhaust gas treatment

Carry out chemical interactions to convert toxic gases into less toxic products thanks to special catalysts. Done in reactors.

How are chemical methods used in exhaust gas treatment

- Thanks to the chemical reactions in this method, the toxic gases in the exhaust gas are completely reacted converted into non-toxic gases.

- Adsorptionprocesses are between chemical substances that have chemical reactions with the adsorbent material. The molecular binding force in this method is stronger than in physical adsorption. Therefore, the amount of heat emitted is greater, and more energy is needed, helping the process to quickly and thoroughly treat pollutants.

- Specifically, the chemical reactions occurring in this method are as follows:

- Liquid compounds such as: Water, basic solutions: KOH, NaOH, Na2CO3, K2CO3, Ca(OH)2, CaCO3… completely absorb some gases such as: C, CO, CO2, NOx are in the composition of exhaust gases, adding catalysts to the process of converting molecules Gas molecules need to be processed into the liquid phase through the process of dissolving chemicals when they come into contact with each other to form new compounds that are completely soluble in water, less toxic, or non-toxic to the environment.

- Thanks to the chemical reactions in the chemical method, some factories have chosen alternative chemicals during the production process to minimize the production of new substances that cause harmful effects. environmental pollution such as ferrous metallurgy factories, …

Exhaust gas treatment methods by chemical method

Thus, treating exhaust gas with chemical methods is essentially a treatment method applied chemical absorption method and chemical adsorption for treatment equipment.

Exhaust gas treatment by absorption method

What is the absorption method?

Chemical absorption of exhaust gases is a method of using liquids and solids. To make materials to absorb toxic gases from the factory’s production process.

This is the process of transferring toxic gases that need to be treated into the liquid phase. Thanks to the dissolution process, they come into contact with each other. During the absorption process, a chemical reaction occurs.

Exhaust gas treatment technique by absorption process is also widely used to dehumidify the air. Toxic and odorous gases in exhaust gas. It helps recover clean vapors and gases mixed in the air or exhaust gas.

>Image of exhaust gas treatment mechanism using absorption tower

Mechanism of treatment technique using absorption method includes 3 steps

- Step 1: Diffusion of gaseous pollutant molecules in the exhaust mass to the surface of the absorbent solution

- Step 2: Penetration and dissolution of the gas into the surface of the absorbent solution.

- Step 3: Diffusion of dissolved gas on the separating surface deep into the absorbing liquid

During the absorption process, pollutant gas particles in the exhaust gas are retained on the surface of solid materials and cleaned. Harmful gases that are trapped are called absorbents.

The activities of dehumidifying the air, removing harmful gases and odors in the exhaust gas, and recovering valuable vapors and gases are called absorption processes.

Commonly used absorbents

- Water (H2O)

- Basic solutions: KOH, NaOH, Na2CO3, K2CO3, Ca(OH)2, CaCO3,…

- Monoethanolamine (OHCH2CH2NH2), Dietanolamine ( R2 – NH), tritanolamine (R3– NH).

Application of chemical absorption method

- Treatment of polluted emissions.

- The absorption method can treat exhaust gas with large emissions flow.

- The absorption method is often used to treat SOx, HCl, H2S, HF, Cl2 gases, NOx, acetone,…

- Substances can be recovered for recirculation or transfer to another production step.

Exhaust gas treatment by chemical adsorption method

What is the adsorption method?

Adsorption is the phenomenon in which gas, liquid, and ionmolecules are retained on the phase interface. The phase interface is very diverse and can be gas-liquid, gas-solid and liquid-solid.

Exhaust gas treatment by adsorption method is a treatment process based on gas separation by the affinity of some solids with some gases present in the gas mixture.

During that process, pollutant gas molecules in the exhaust gas are trapped on solid materials. The application of adsorption method to treat gas sources with small impurity gas and vapor content.

To clean and dry air, separate gas mixtures. Or the vapor forms individual molecules, carrying out the process of heterogeneous influence on the surface.

The solid material used in this process is called an adsorbent.

The gas trapped in the adsorbent is called the adsorbate.

Chemical exhaust gas adsorption is a method by which gases are adsorbed. Due to the chemical reaction with the adsorbent material, the molecular bonding force in this case is stronger than in physical adsorption.

Therefore, the amount of heat released is greater, and more energy is needed.

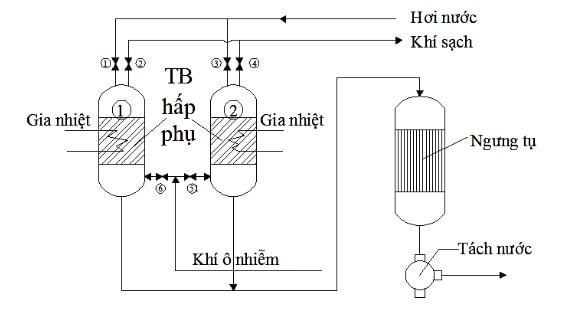

>Image of exhaust gas treatment mechanism using adsorption tower

The mechanism of the adsorption treatment process includes 3 steps

When carrying out adsorption in tower 1. The exhaust gas is introduced at the bottom of the tower (open valve 6 and close valve 5).

Gas passing through the layer of adsorbent material is heated to increase adsorption capacity. Here the gases that need to be treated are trapped in the material layer. Clean gas goes out through a pipe with valves (valve 2 is open, valve 1 is closed).

While tower 1 performs the adsorption process, tower 2 carries out material reduction.

Steam is introduced into tower 2 from top to bottom (valve 3 opens, valve 1 closes).

Steam passing through the material layer will carry the pollutants out to the condenser, separating the water from the pollutants. Contaminated gas will continue to be treated.

When the material in tower 1 has exhausted its adsorption capacity, reconstitute the material and proceed with adsorption in tower 2.

Desorption. Desorption is an important stage of the adsorption cycle. Confirming the economics of the exhaust gas cleaning process. This process aims to restore the inherent activity of the adsorbent and is the reverse adsorption process.

Application of adsorption method

- Not flammable or difficult to burn

- Valuable and needs to be recovered.

- There is a low concentration in the exhaust gas that other processes cannot apply.

- Used to adsorb NH3, SO2, Cl2, mercury vapor,…

Chemical exhaust gas treatment system

Advantages of treating exhaust gas by chemical methods.

- This method helps treat exhaust gases pollution

- Helps treat exhaust gas with large emission flow

- This method helps treat SOx, HCl, H2S, HF, Cl2, NOx, acetone,…

- Highly effective exhaust gas treatment

The application of chemical exhaust gas treatment is an effective advanced method. Bringing people as well as the earth a fresh atmosphere, avoiding harmful agents.

With the information about chemical methods in exhaust gas treatment we hope to get some advice. Useful reference for how to treat exhaust gas before releasing it into the environment. Please contact Hasy Environment for more detailed advice.