Traditional exhaust gas treatment technologies such as adsorption, absorption and filtration methods. Has been developed to handle exhaust streams from stationary sources.

These treatment methods generate waste that needs to be treated or the adsorbent material must be reconstituted.

They are gradually becoming obsolete due to ever-evolving technology. Besides that, there are policies on environmental protection.

Therefore, it is necessary to research a new processing technology that is friendly to the environment.

And a suitable replacement technology has been born, which is exhaust gas treatment with biological filtration technology (Biofilter).

Biofilter has received much attention and use in Europe, especially in Germany and the Netherlands, during the past 15 years.

What is the concept of biological filtration technology (Biofilter) in exhaust gas treatment?

Biological filtration (Biofilter) is a new air pollution control (APC) technology commonly used today.

In this technology, the exhaust gas contains appropriate substances. volatile organic compounds (VoCs), carbon compounds, or inorganic toxic gases – ammonia, H2S. Passed through a filter material containing microorganisms to oxidize and remove pollutant compounds.

This technology has been successfully applied in Germany and the Netherlands in odor control, VoCs and toxic emissions from many industrial sources and livestock areas.

More than 90% control effectiveness on many common air pollutants. Treats hydrogen sulfide (H2S) to 95% and ammonia to 65%. Due to low operating costs.

Biofilter can offer significant economic advantages over other APC technologies. If applied to exhaust gases containing biodegradable pollutants at low concentrations. Environmentally friendly because of low energy needs and minimal use of chemicals.

System custom handlingwaste removal with Biofilter technology

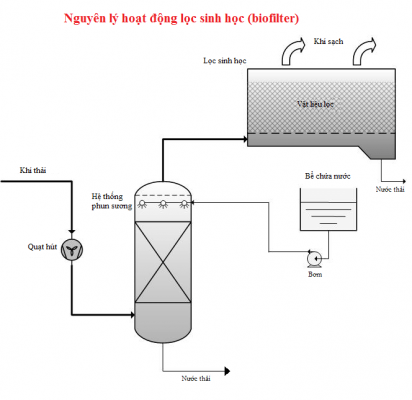

Principle of operation of the exhaust gas treatment system using Biofilter technology

In the exhaust gas treatment system using biological filtration technology (Biofilter). Exhaust gases are carried upward through a layer ofbiological material. For example, coconut fiber, sawdust, bagasse…

The filter material carries a thin water film that is home to microorganisms.

Pollutants in the gas stream are retained in the filter material through adsorption and absorption. It is then decomposed by microorganisms.

Thevial material layerc is where the necessary nutrients are provided tomicroorganisms. The products of the decomposition process are CO2 gas, water (H2O) and sulphate and nitrate salts.

The purified air flow escapes to the top of the biological filtration system (Biofilter) to enter the environment.

Most biological filtration systems (Biofilter) today. Effective in treating odors and volatile organic substances greater than 90%.

Factors affecting the biological filtration system (Biofilter)

Moisture in biological filters usually ranges from 40% – 60%. To prevent the filter material layer from drying out, the exhaust gas needs to be moistened first.

The exhaust gas must have a humidity of about 95% before entering the biological filtration system. In practice, the exhaust air is pre-humidified with a misting system

Natural filter material contains enough different types of microorganisms to process easily decomposable substances. In the case of substances that are more difficult to decompose.

The filter material can be supplemented with special cultures so that the filter material works well to ensure output parameters.

Supplementation ofminerals and nutrients is necessary if there are insufficient nutrients in the filter media.

In a biological filtration system, the filter material needs to have a pH of 6-7.5 for microorganisms to function well. The decomposition rate decreases rapidly at pH below 6.

The retention time of gas in the biofilter must be at least 30 – 45 seconds for odors and pollutants to be effectively removed. Typically, the residence time of biological filtration systems ranges from 30 seconds to 1 minute

Advantages and disadvantages of exhaust gas treatment system using biological filtration technology (Biofilter)

|

Advantages

|

Disadvantages

|

If you need to install an exhaust gas treatment system at a reasonable cost and environmentally friendly Biofilter technology will be the right choice. Please call us immediately at 0972221608 or website https://xulymoitruong360.com/ Any questions you have about the biofilter technology exhaust gas treatment system (Biofilter) will be answered. answered by HASY ENVIRONMENT.