Emissions from factories, workshops or combustion gases from waste contain many toxic components such as CO, H2S, HCL, SO2, HF, ash, dust…

These toxic gases greatly affect human health and life, seriously polluting the atmosphere, affecting animal and crop productivity.

You can refer to the article about air pollution in Hanoi collected by us.

Investing in and equipping factories and workshops with an exhaust gas treatment system such as a treatment tower exhaust is necessary and mandatory. To ensure that emissions into the environment meet allowed standards and do not pollute the air environment

Exhaust gas absorption treatment tower

Absorption tower

Operating principle of absorption tower

Absorption tower is a type of exhaust gas treatment tower that uses liquid to remove pollutants from exhaust gases.

The gas flow containing pollutants goes from bottom to top, the absorbent solution is sprayed from top to bottom.

When the exhaust gas comes into contact with the absorption solution. Pollutant components will be retained in solid form while clean air will escape.

The solid residue is washed down by the water and periodically discharged as sludge.

Types of absorption towers

- Hollow gas washing tower: in which the autoclaving solution is sprayed into small drops in the empty volume of the tower and allowed to pass through the gas stream.

- Bubbling type absorption tower: in the tower, air is passed through a flat perforated plate, above the absorption solution. Exhaust gases pass through the water layer in the form of air bubbles and burst at the top of the water surface. The process of capturing dust particles and absorbing pollutants occurs on the surface of air bubbles.

- The absorption tower has a layer of buffering material: buffer tower Usually a tower containing a layer of hollow material made of ceramic, metal or plastic. Exhaust gas is led in at the bottom of the tower and exits at the top of the tower. The absorbent solution is sprinkled evenly onto the top of the cushion layer and flows along the surfaces of the cushion material. The absorption reaction occurs on the wet surface of the pad layer.

Advantages of absorption tower

- High efficiency, especially for exhaust gases with good solubility

- Simple operation and repair

- Common-use, reconstituted absorbent solution

- In addition to exhaust gas treatment, dust treatment can also be combined.

Disadvantages of absorption tower

- Requires regular maintenance and can be quite severely corroded

- If reconstitution is used, there is a cost to reconstitute the solution

- If not reconstituted, it must wastewater treatment

Adsorption exhaust gas treatment tower

The pollution in exhaust gas adsorption tower has the structure such as a dust filter made of hollow materials.

Pollutants in the exhaust gas when passing through the adsorbent layer are retained thanks to the adsorption phenomenon.

Adsorbent materials have a granular structure, each particle contains an extremely large number of tiny pores capable of adsorbing without any chemical reaction with poison gas.

In practice, activated carbon, activated kaolin, geolite, silica gel are often used…

Depending on the concentration of the pollutant, people construct a thick or thin layer of adsorbent material. And depending on the particle structure of the adsorbent material, choose the air flow speed passing through the material layer. So that the air resistance is not too high and the toxic vapor filtration efficiency must meet the set requirements.

With the particle size of the adsorbent material being 1 – 3 mm spherical or cylindrical, the filtration speed should be 0.5 – 1.5 m/s.

Filtration speed should be reduced when toxic concentrations are high in the exhaust gas. The air resistance of the device is about 60~80kg/m2 for every 100 mm of adsorption layer thickness.

After a while, the adsorbent cannot adsorb any more toxic gases. People can dispose of it with waste or reconstitute the adsorbent.

Toxic gases released from the reconstitution process often have very high concentrations. So people often use the burning method to remove toxic gases before discharging or passing through other recycling stages.

Adsorption tower operating principle

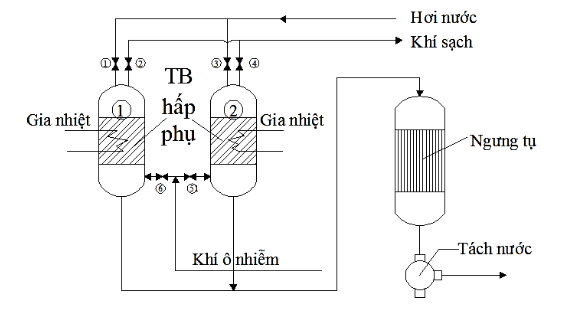

Adsorption tower operating principle diagram

When conducting adsorption in tower 1: Exhaust gas is introduced at the bottom of the tower (open valve 6 and close valve 5).

The gas passing through the adsorbent layer is heated to increase adsorption capacity, where the gases that need to be treated are retained in the material layer. Clean gas goes out through a pipe with valves (valve 2 is open, valve 1 is closed).

While tower 1 performs the adsorption process, tower 2 conducts material reconstitution.

Steam is introduced into tower 2 from top to bottom (valve 3 opens, valve 1 closes).

Steam passing through the material layer will carry pollutants out to the condenser. Separate the water from the pollutant, and the polluted gas will continue to be processed.

When the material in tower 1 has exhausted its adsorption capacity, reconstitute the material and proceed with adsorption in tower 2.

Desorption : desorption is an important stage of the adsorption cycle. Confirming the economics of the exhaust gas cleaning process. This process aims to restore the inherent activity of the adsorbent.

Advantages of adsorption exhaust gas treatment tower

- Adsorbents are cheap and easy to find.

- Simple operation, low energy consumption.

- Can handle low concentrations and high flow of pollutants.

- High processing efficiency

Disadvantages of adsorption exhaust gas treatment tower

- Not suitable for treating large concentrations of pollutants.

- The device is bulky and takes up a lot of space

- Exhaust gas must be filtered before entering the treatment system

If you are in need of an exhaust gas treatment system, please call 097 222 1608 to get advice on choosing Hasy Environment choose in the most detailed way

Some emissions projects Hasy Environment implemented